Closed Loop Cooling Systems

Closed-Loop Water Cooling System for Ozone Generators

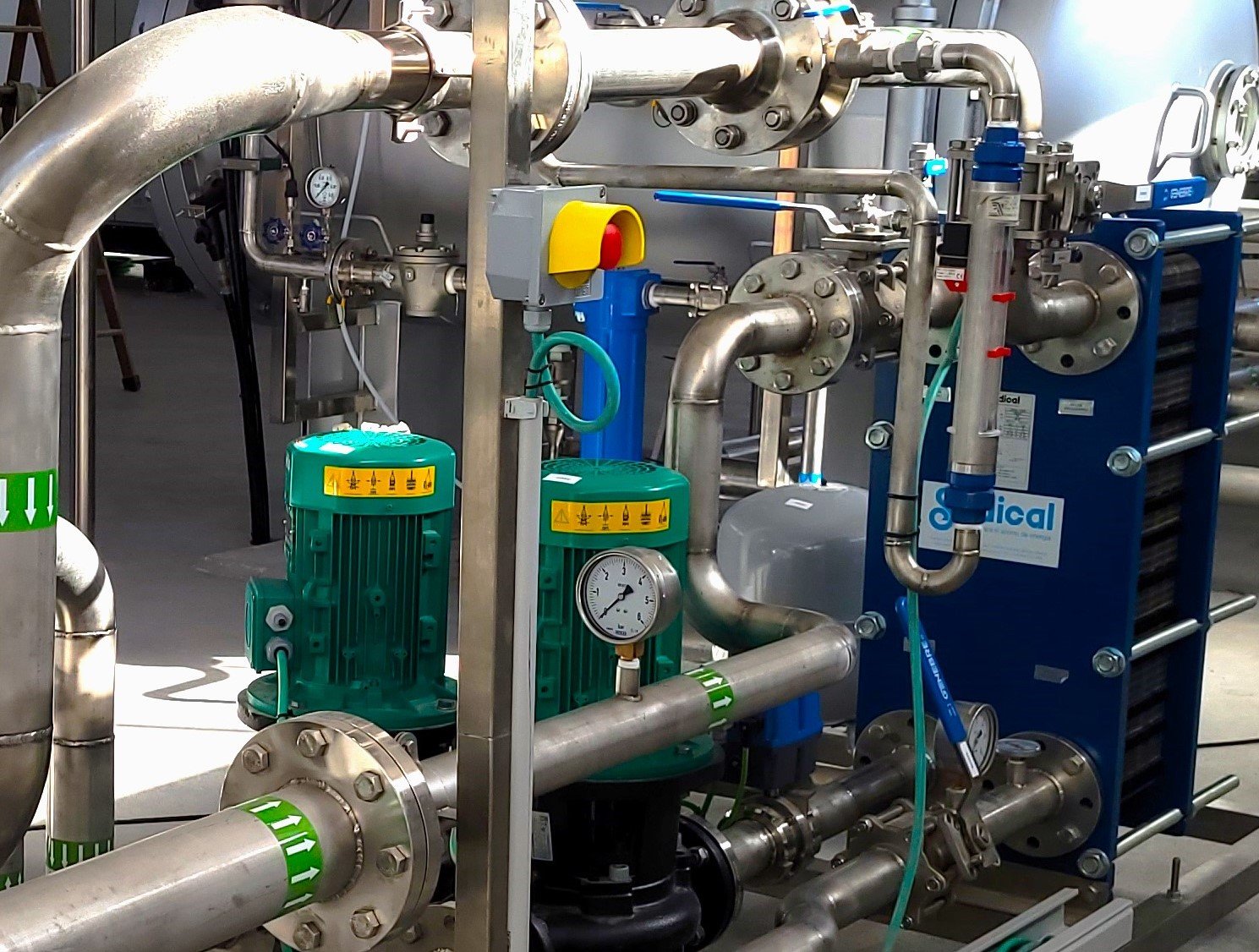

Longking designs and manufactures a closed-loop water cooling system to ensure the optimal performance and longevity of its ozone generators. Each unit is equipped with high-quality components for efficient heat dissipation and reliable operation.

System Components:

✔ Plate Heat Exchanger – Ensures efficient thermal transfer for stable cooling performance.

✔ Impulse Pumps (Hot Side) – Two units, with one in reserve for uninterrupted operation.

✔ Flow Measurement Rotameter (Cold Side) – Monitors cooling water flow for optimal regulation.

✔ Thermometers (Hot & Cold Side) – Provides real-time temperature monitoring.

✔ Pressure Gauges (Hot & Cold Side) – Ensures safe and controlled pressure management.

✔ Gas Purge Circuit – Removes trapped gases to maintain system efficiency.

✔ Expansion Vessel – Absorbs pressure fluctuations and ensures system stability.

✔ Isolation Valves – Allows for easy maintenance and system control.

This advanced cooling system enhances efficiency, durability, and performance, ensuring stable ozone generation under demanding industrial and municipal applications.

Customized Heat Exchanger Selection & Design

At Longking EnTech, each heat exchanger is carefully calculated and selected based on the specific requirements of each application. The system is tailored by adjusting:

✔ Number and Type of Plates – Optimized for efficiency and performance.

✔ Class & Thermal Length – Ensuring precise heat transfer based on operational needs.

✔ Size, Joints & Connections – Adapted for seamless integration into the cooling system.

✔ Material Selection – Chosen for durability and compatibility with process conditions.

Additionally, the design and assembly of components can be customized to match space constraints and client specifications, ensuring a flexible, efficient, and perfectly integrated cooling solution.